The BEACON UV

The Wogaard Beacon UV is a unique coolant disinfection solution that effectively penetrates through milky soluble coolant mixes to reduce bacteria growth down to levels that comply with the current regulations and are safe for operators.

|

The Main Benefits :

Typical Application:

|

To determine the readiness of potential users for the application of the Wogaard Beacon UV Disinfecting Solution, certain information is needed. We would greatly value your time and cooperation in answering the Customer Qualification Questionnaire:

Specification:

The Wogaard Beacon UV system's simple-to-use interface will ensure an easy operation of an automated process and it’s accessible for all many types of machine sumps. The Beacon UV installation is straightforward and can be set up whilst the machine is still in operation.

Low bacteria concentration levels in machines’ coolant will provide major environmental and economic benefits to your facility!

The Wogaard Beacon UV system's simple-to-use interface will ensure an easy operation of an automated process and it’s accessible for all many types of machine sumps. The Beacon UV installation is straightforward and can be set up whilst the machine is still in operation.

- Stand-alone mobile system.

- Can be used in multiple machines once the process is finished in one of them

- Around 24-36 hours will be necessary to disinfect the whole amount of coolant contained in the main machine sump.

- The number of machines that the unit can treat will depend on the size of the sump and treatment time required on each machine as bacteria will return after the treatment.

Low bacteria concentration levels in machines’ coolant will provide major environmental and economic benefits to your facility!

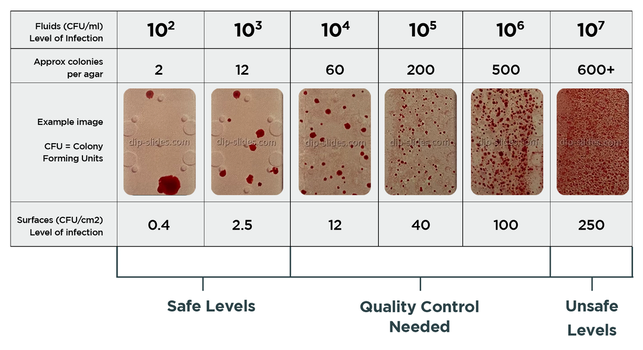

Bacterial contamination in cutting fluids:

Low bacteria concentration levels in machines’ coolant will provide major environmental and economic benefits to your facility!

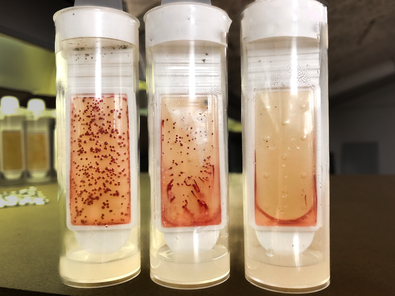

The example below shows coolant samples before and after treating the machine with the Wogaard Beacon UV

Low bacteria concentration levels in machines’ coolant will provide major environmental and economic benefits to your facility!

The example below shows coolant samples before and after treating the machine with the Wogaard Beacon UV

|

The following table indicates what can be regarded as good, reasonable and poor standards of fluid management, and also what action needs to be taken. Results are expressed in terms of colony-forming units per millilitre (CFU/ml) of fluid.

- <104 CFU/ml - Good control. Bacteria are being maintained at low levels. Regular checks and actions should continue to maintain the fluid quality.

- ≥104 to <106 CFU/ml - Reasonable control. Review and take action to check the quality of the metalworking fluid and adjust fluid parameters to those recommended by the supplier. If bacterial growth continues despite these adjustments, add biocide at the dose recommended by your supplier.

- ≥106 CFU/ml - Poor control. Immediate action should be taken in line with the risk assessment. Normally draining and cleaning should take place

|

More information about bacteria contamination in cutting fluids here

|