THE BENEFITS

All Departments can benefit from our solutions!

HOW COOLANT SAVING POSITIVELY IMPACT

YOUR BUSINESS?

YOUR BUSINESS?

WOGAARD'S COMMITMENT

TO THE INDUSTRY AND THE ENVIRONMENT!

Wogaard launched the unique and innovative Coolant Saver product with a focus on cost-cutting and optimisation for the manufacturing industry.

Many companies from a wide range of industries from Aerospace, Automotive, Medical, subcontract and many more have enjoyed great cost saving and environmental benefits of the award-winning products.

Many companies from a wide range of industries from Aerospace, Automotive, Medical, subcontract and many more have enjoyed great cost saving and environmental benefits of the award-winning products.

Wondering how relevant would your coolant savings be? Download our Cost Saving Calculator.

OUR SOLUTIONS

REDUCE - REUSE - RECYCLE!

A simple solution that has a great impact! Specifically design for CNC machines, Wogaard Saving Oil Solutions are easy-to-install and do not require of any external power source to operate.

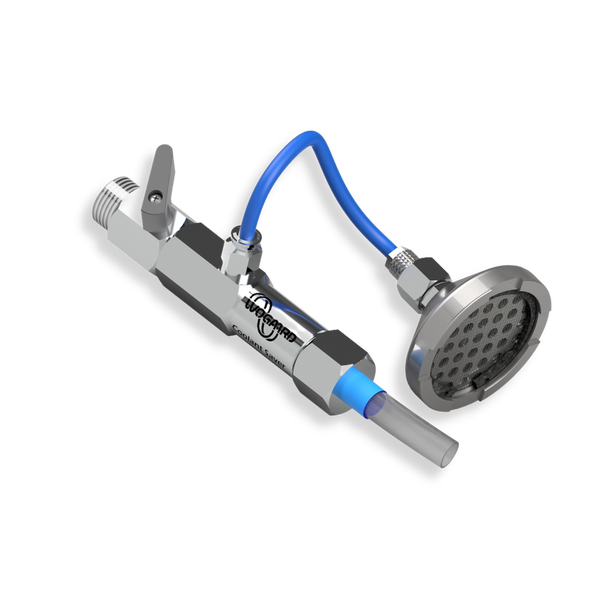

COOLANT SAVERSoluble Coolant

Reclaim soluble coolant that accumulates in the swarf bins and return it into the machine's main reservoir.

|

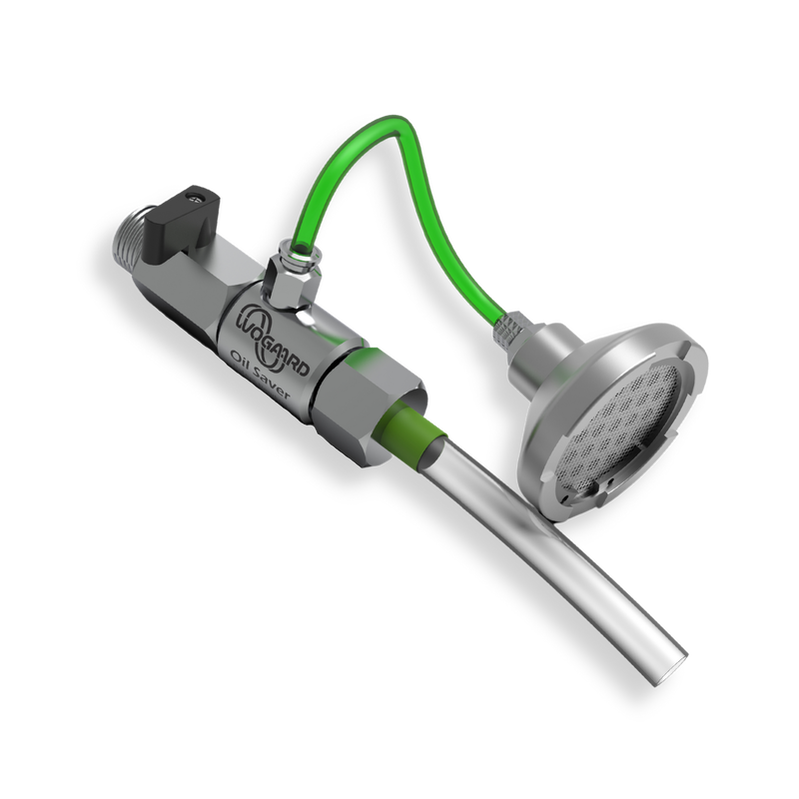

OIL SAVERNeat Oil

Reclaim neat oil up to 32cs thickness that accumulates in the swarf bins and return it into the machine's main reservoir.

|

SWARF BIN COVERS

Customised Dimensions

Reduce employe's exposure to harmful vapours and improve housekeeping with the 'Keep-It-Covered' solution.

|

WOGAARD A/B BOX2x Vacuum Cups, 1x Unit

Expand and Automate your Coolant Saving Management by adding 2 Vacuum Cups to a Coolant or Oil Saver unit.

|

WOGAARD BEACON UVDisinfection System for Bacteria Control

An Innovative UV Coolant Disinfection System for Bacteria Control in low-light absorbency cutting fluids.

|

Check the rest of Wogaard Solutions here

WOGAARD'S FOCUS

GREENING MACHINING - A PATH TOWARDS SUSTAINABLE MANUFACTURING

|

At the heart of the machining industry there is a strong mindset of never ending improvement and optimisation. Always striving to become better, faster, smarter and more efficient. It is the evolution of industry in motion. Those who can adapt and improve will win.

The term Sustainable Manufacturing could be defined as: "The creation of manufactured products that use processes that minimise negative environmental impacts, conserve energy and natural resources, are safe for employees, communities, and consumers and are economically sound.” |

SUCCESS STORIES

Also a few words from real Case Studies from renown businesses in the manufacturing industry:

|

Technoset - Techno Group

|

Seco Tools UK

|

B-Tech Engineering

|

Sub-CNC Precision

|

“We calculated the cost of the coolant at £1,285.92 and added the cost of disposal at £304.50 for every 4,000 litres, which highlighted an annual expenditure of just under £1,600 for one machine alone.”

Phil Ketch, Continuous Improvement Team, Mettis Aerospace.

Phil Ketch, Continuous Improvement Team, Mettis Aerospace.

“We have significantly reduced the time wasted topping up the oil in the sump of the machines,negated the risk of neat oil being spilt or leaking onto the shop floor and saved our labourers’ time vacuuming out the oil from the skips.”

Jon Davis,Engineering Group Leader, Renishaw.

Jon Davis,Engineering Group Leader, Renishaw.

“There is simply no way we would go back to a shopfloor without the Coolant and Oil Savers fitted to the machines. Walk around now and the swarf bins are dry with material that is ready to be responsibly recycled.”

Kevan Kane , Managing Director, Technoset.

Kevan Kane , Managing Director, Technoset.

“Since we have had them fitted, not only are the operators happy with the results, but it will also have a major impact on our environment, especially as we pursue ISO 14001 accreditation.”

David Wain, Plant Manager, Cook Compression.

David Wain, Plant Manager, Cook Compression.